Custom Packaging Design Services

Product packaging design is almost as important — if not as important — as the product itself. In a highly competitive market like the food industry, you have just milliseconds to connect with consumers and communicate your brand; just look at the multitude of choices in the cereal aisle or the sheer number of bottled water brands. With such a saturated market, it’s imperative to work with reliable design and packaging companies that will help you create the best possible packaging and label design for your product.

High-Quality Packaging For Your Product

At GCE Packaging, our team can workwith you to create durable, aesthetically pleasing packaging that meets your product’s needs and connects with consumers. When creating custom packaging, our skilled design team takes several important factors into consideration, including:

- Transport and Product Protection

- Packaging Material

- Product Labeling

Speed to Market

By choosing a co-packer that combines innovative packaging design services with reliable contract packaging, you can greatly reduce your time to market.

To provide the highest-quality contract packaging services, we make use of over 200 packaging machines — allowing us to quickly and efficiently get your product out the door and into consumers’ hands. We can fulfill orders both small and large for a wide range of clients, from small businesses to Fortune 500 companies.

Cost Savings

In addition to catching your consumer’s eye, your product must also be profitable. By taking material types, shipping costs, and product waste into consideration, we can create a custom packaging design solution that is not only attractive but also provides cost savings.

Investing in innovative, attractive packaging design is a truly cost-effective way for emerging brands to get noticed by consumers. And for current brands that want to retain or increase their market share, smart, reliable packaging will keep them ahead of the curve.

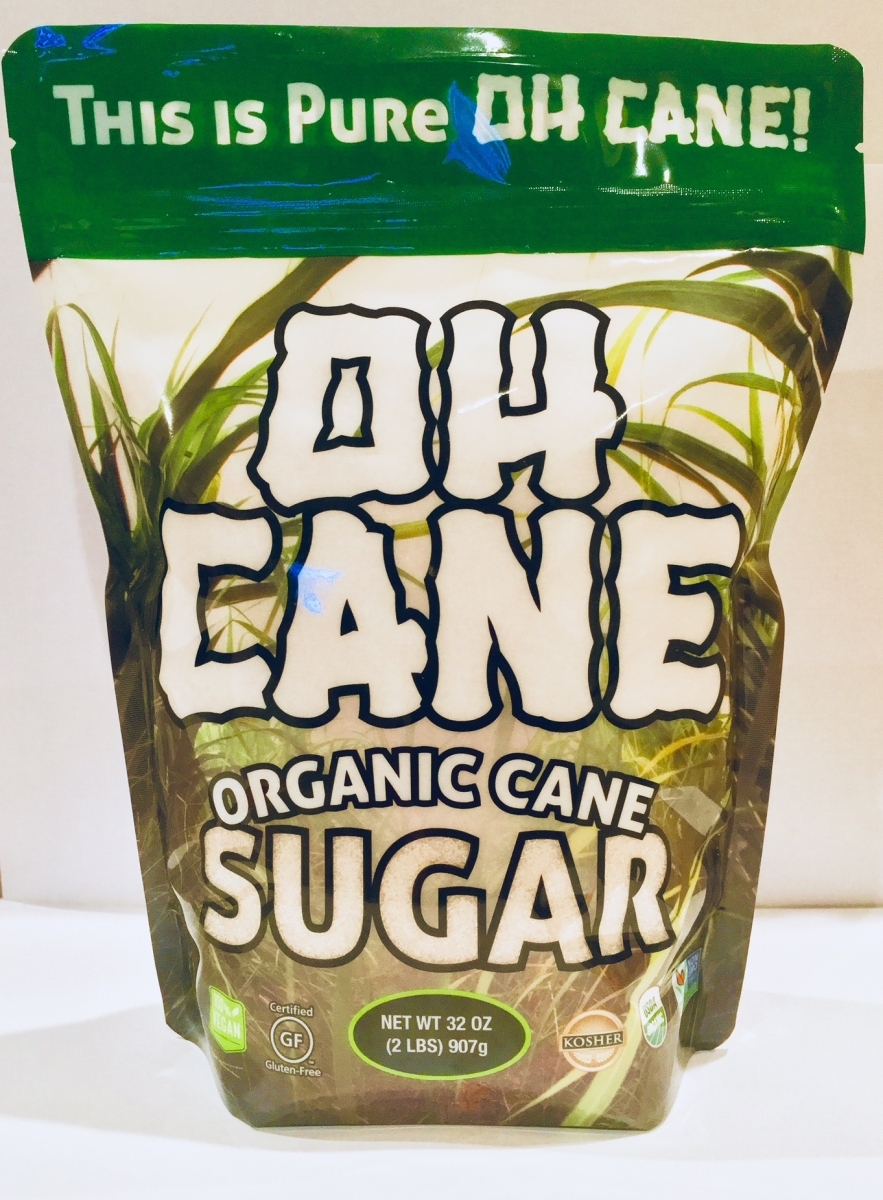

Pouch Contract Packaging

At the core of our packaging services is our flexible film pouch filling capabilities; we’ve been supporting our customers with this versatile service. We utilize state-of-the-art vertical form fill machines which offer up to three sealing surfaces, and allow for the use of almost any packaging film. Specialty pouches can also be accommodated, such as stand up and spouted pouches. Filling of dry is handled in the same method with the same quality and attention to detail.

Staying up to date is important in the contract packaging business.One of the fastest growing packaging trends has been the birth and popularity of the stand-up pouch. At GCE Packaging, we have invested in the technology to process and fill these pouches. With dedicated food facility, we can process just about any type of product into a stand-up pouch.

We also have the ability to handle a large array of filling weights and volumes into these pouches. In a stand up pouch, the opportunities are endless. We utilize high speed batch coding equipment to mark each unit with a lot code and expiration date. Let us offer you a turn-key solution. We offer aggressive sourcing for printed stand-up pouches to utilize on our stand-up pouching equipment.

Supply Chain Services

Distribution & Pool Distribution

• 1400+ network facilities

• Last Mile Solutions

• Pool Distribution

• Regional Line-hauls

Warehousing & Fulfillment

• Quick Turn Replenishment

• Receiving, Storage, Shipping

Pool Distribution

• Retail distribution facilities – national footprint

• Regional connectivity streamlining product flow

• Full visibility of all shipments, real-time status

• Retail store consolidation and distribution

• Mixed vehicle fleet for optimization of routes

State of the Art Packaging Facilities

Whether packaged in our Brasil or South Plainfield, NJ (U.S.) facility, owe have the capability to pack at a rate of 35 – 60 bags per minute depending the packaging size. Our production lines have a 3 phase food safety process to ensure the integrity of the finished product.

- Screening: All sugar passes through a sift screening to remove any micro particles.

- Magnetic Screen: All sugar passes through a magnetic draw box to ensure no metal particles exist.

- Metal Detection: All packaged sugar pass through a metal detector.

Providing Our Customers With High Quality Product That Exceeds Food Safety Standards Is Our Goal

Pouching and Bagging Services

- Many Sealing Choices—Our precision-engineered automatic equipment can pouch bulk product with a variety of different sealing techniques, including impulse or band seals.

- The Material Difference—We can construct a pouch to your specifications from polyethylene, polypropylene, various laminates, poly paper, poly foil, Tyvek® and many other materials. All pouching materials are available plain, print registered, or random print orientations.

- Low Cost Automatic Operations—Our form-fill-seal pouching lines are fully automatic, saving time and money on every job. We also offer automatic pouching with seals on three or four sides, assuring you consistent quality at an exceptionally low cost.

- Specialized Services—Weight verification, metal detection, and labeling services are available. As needed, these specialized services will be incorporated into your pouching process.

- Flexible Resources—In addition to meticulously maintained machinery, we offer two production shifts to ensure that each order gets completed in a timely manner.

Next Steps…

Design your private packaging with the packaging experts